We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

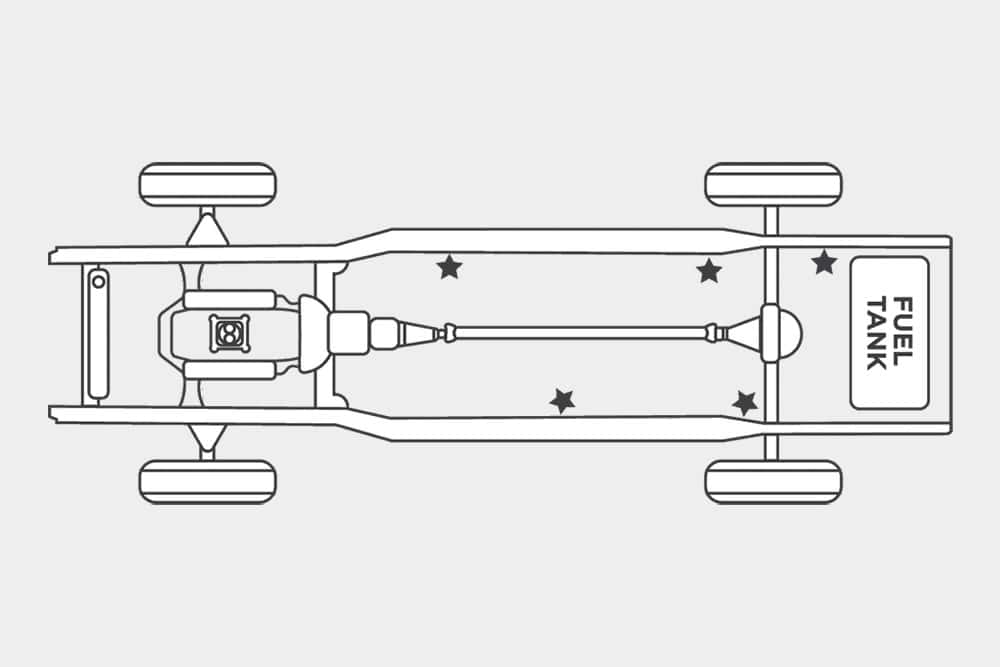

Universal Fuel Pumps

Carter offers an array of universal fuel pumps for marine, off-road and passenger car applications.

- 100% factory tested and approved

- Offered in a variety of applications, depending on vehicle need

- Feature exclusive CleanScreen™ technology*

Universal fuel pumps and kits can include the following components**:

- Fuel pump

- Tank seal

- Strainer

- Grommets

- Wire harnesses

With an in-tank fuel pump, impurities tend to enter the path over time and affect the fuel flow. The impurities eventually build up and can cause corrosion, which can damage the electrical integrity of components and mechanical aspects of the pump.

Carter exclusively provides CleanScreen™ multilayer filtration technology*. This provides 40% more dirt holding capacity* to effectively trap all levels of microns, which helps preserve the electrical integrity of the fuel pump, thus increasing life.

*Application specific

**Product specific

Available designs include:

Rotary Vane

Originally created for military use, this configuration has been in production longer than any other Carter model. Rotating vanes driven by a heavy-duty wet motor deliver pressure from 4 to 18 psi at a flow rate of up to 100 gallons per hour. This provides excellent lift and prime capability. The pump is available in 6-, 12- and 24-volt versions. It is appropriate for RV, marine, agricultural, industrial and performance applications.

Carter geroter

Carter geroter universal pump applications range from carburetor to TBI & MFI systems. They are commonly used in OE-type hanger and module assemblies. The gerotor utilizes a unique gear and rotor eccentric mechanism that squeezes the fuel within the pump to create high pressure with limited pulsation. Compact, lightweight and fuel-cooled, it is a preferred among many OE manufacturers. EFI marine manufacturers are also installing these robust gerotors to meet their fuel delivery demands.

Solenoid

Ideal for use in 6-, 12-,and 24-volt applications and available in various pressure ranges, this is the most widely used fuel pump. The solenoid pump uses a piston actuated by an electromagnetic coil to generate fuel pressure and flow. By using only short pulses of electricity, the solenoid pump is very energy efficient. It is also long-lasting, with no internal rubber parts or bellows to wear out.

Turbine technology for electrical in-tank fuel pumps is likewise available to improve fuel flow, lower current strain and meet specified engine requirements.